INNOVATION STORY

INNOVATION STORY

INNOVATION STORY

A Trajectory of Challenge

The EBARA Group’s DNA

"Passion and Dedication" was the motto of our founder and words that continue within the Group still. "Both the employees and company shall strive for growth with passion and dedication to bring forth originality and ingenuity, rather than simply fulfilling the task at hand. When working with passion and dedication there is nothing that cannot be communicated to others." With this spirit as our origin, the EBARA Group will continue innovating for the benefit of society.

First Innovator

The history of our founder, Issey Hatakeyama

Moment of Innovation

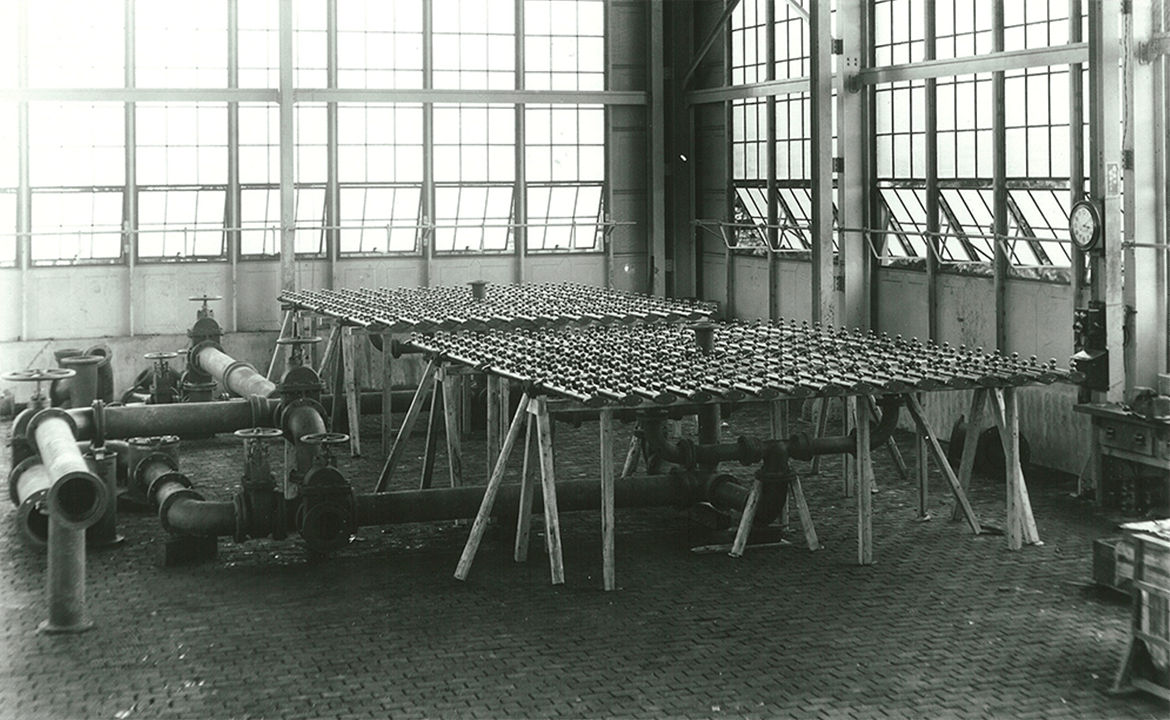

Supporting the modernization of Japan

Since its founding, at a time when imported machinery was the mainstream, EBARA contributed to the industrial development of Japan by actively supplying Japanese-made products to the world.

Having survived the Great Kanto Earthquake and World War Two, the company took on the challenge of developing not only pumps, but also new products such as fans and chillers in order to build the infrastructure that would be essential for Japan's modernization.

EBARA's current technological base is supported by its historic achievements.

- See our products and activities

-

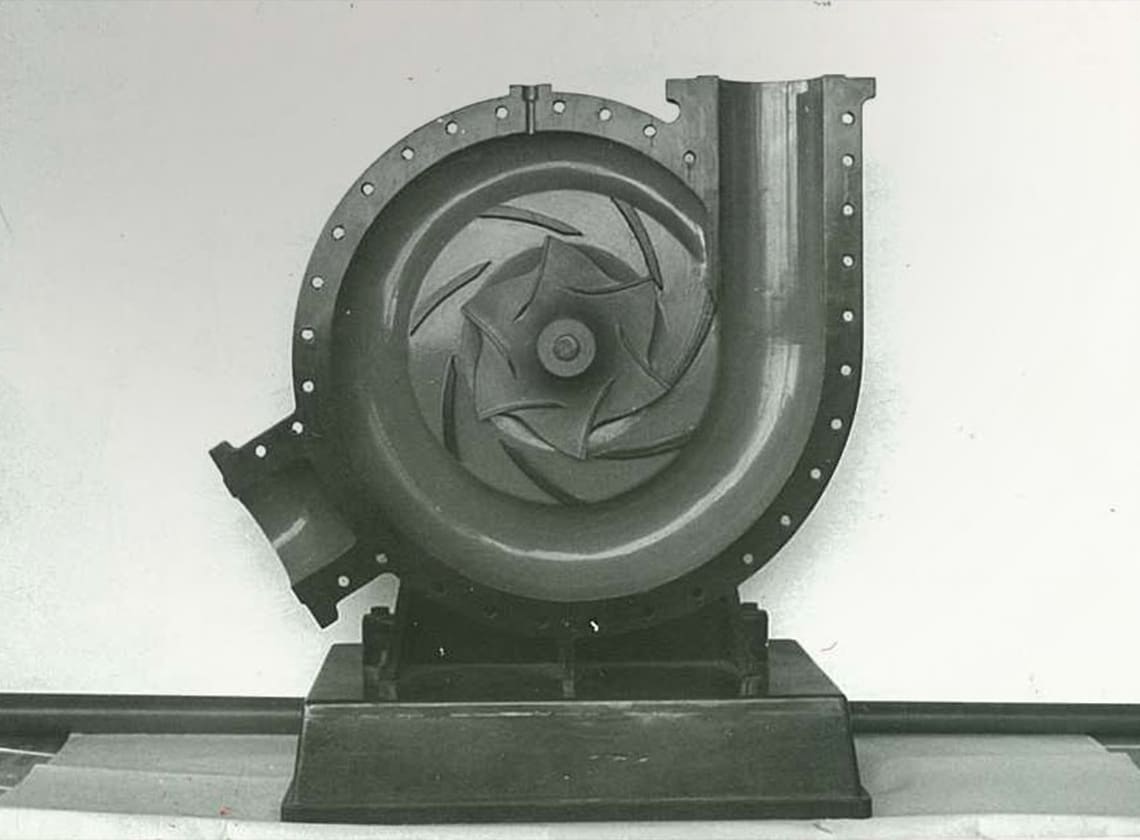

1912

1912Provision of world-renowned centrifugal pumps

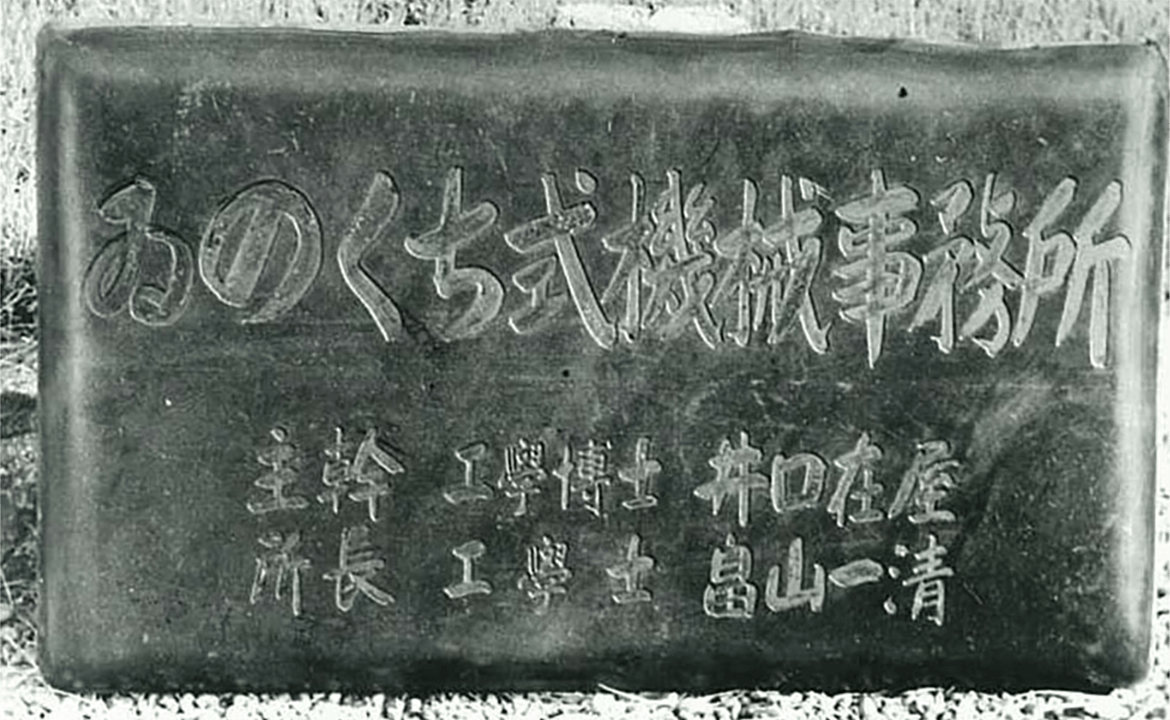

Issey Hatakeyama established the Inokuty Type Machinery Office to provide excellent products based on Dr. Ariya Inokuty's world-renowned theory of centrifugal pumps.

1916

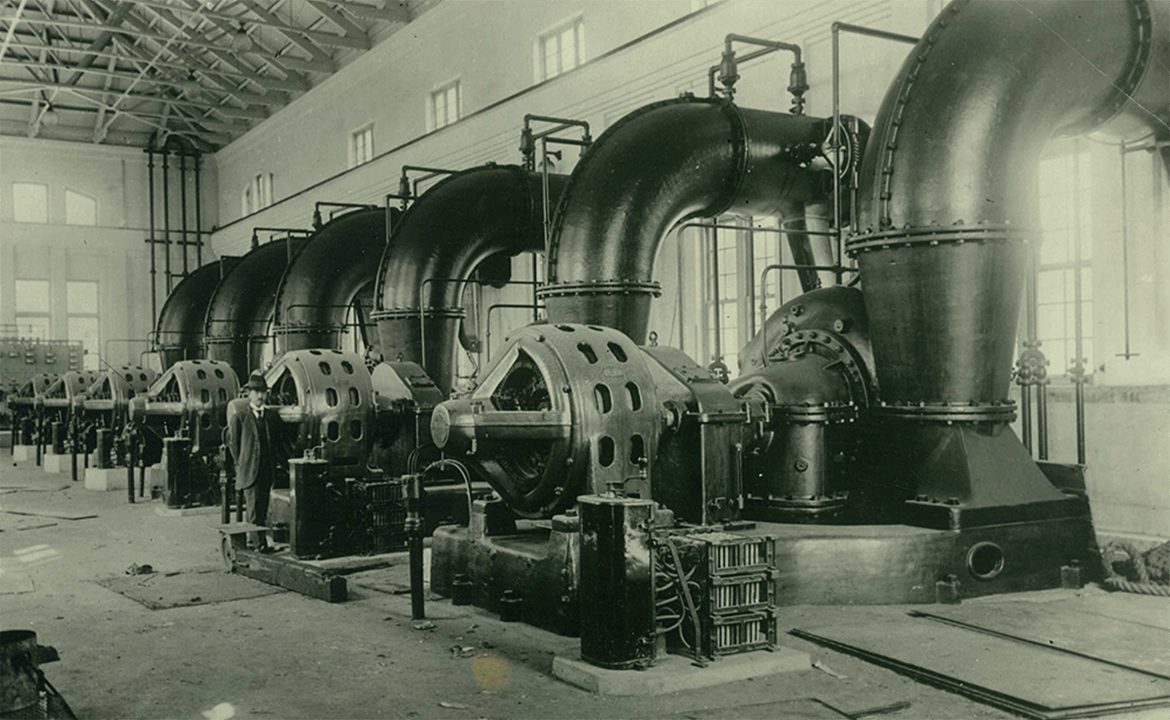

1916Order for Japanese record-breaking large centrifugal pump

At well over 20 tons, the large-scale pump broke the existing record for size.

It is still on display at the head office of EBARA Corporation.

It proved to be the catalyst for the expansion of EBARA’s pump market share. 1924

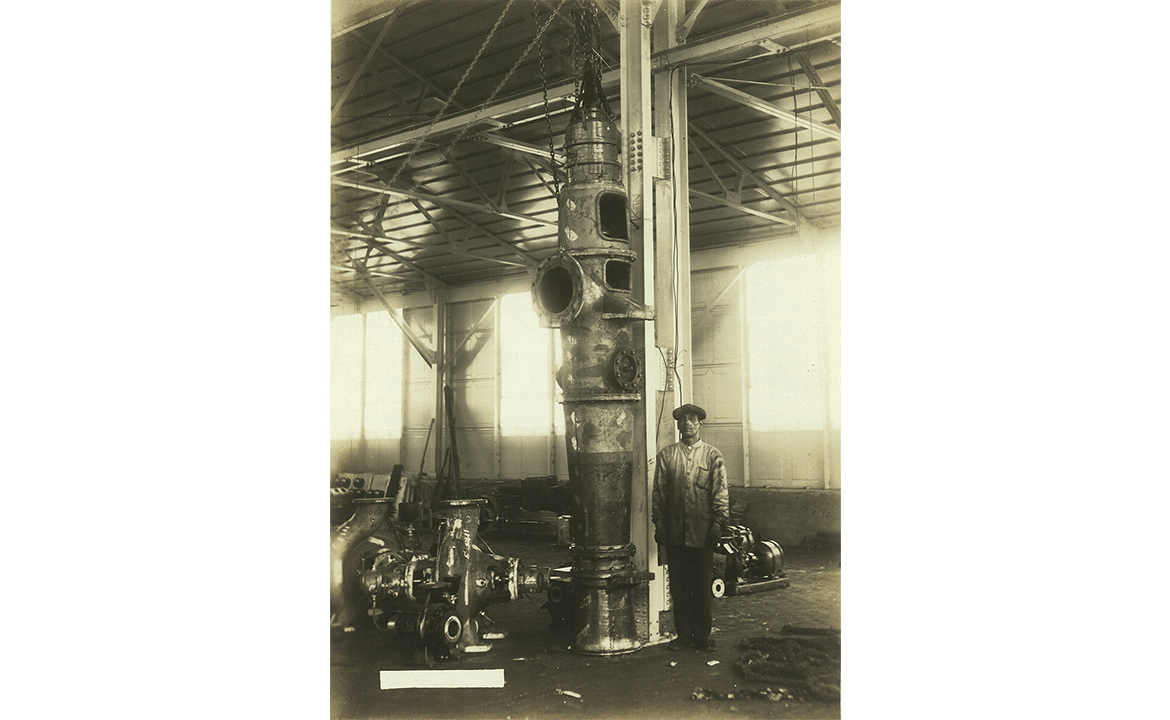

1924Japan's first axial flow pumps

During this period, with the proliferation of land improvement and arable land consolidation projects, demand for large-capacity pumps increased.

EBARA was quick to start to address this, taking the industry by surprise by responding to the demand. 1930

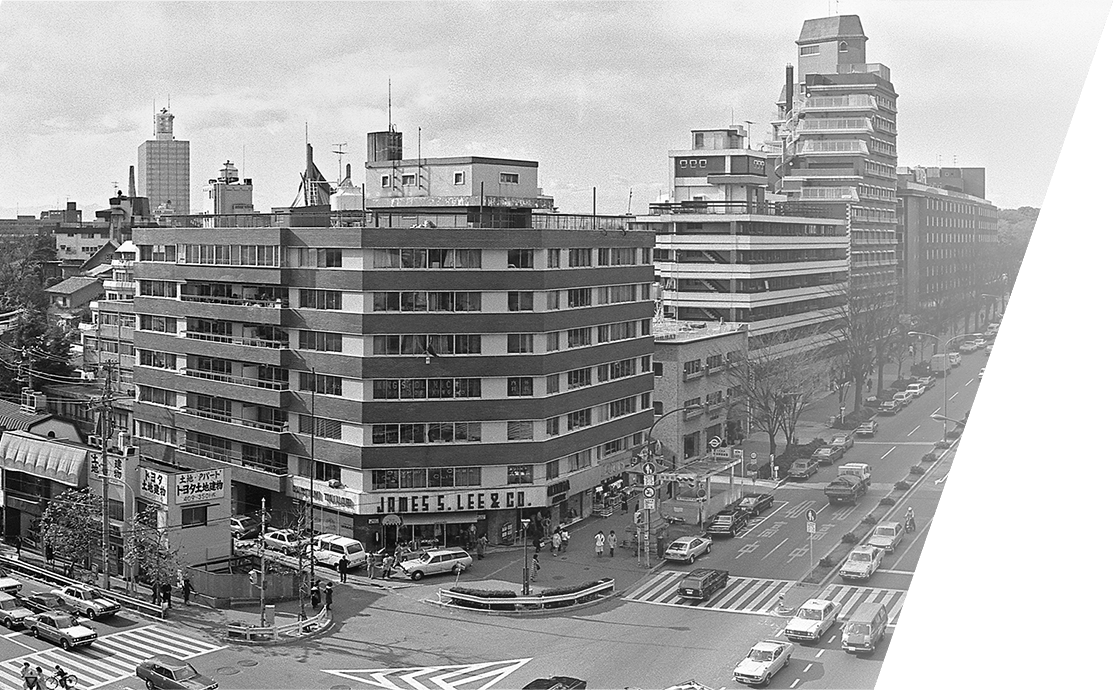

1930Japan’s first centrifugal chillers

Many large-scale facilities such as artificial silk plants, department stores, and so on, were being constructed.

As a result, centrifugal chillers for use in air conditioning were in high demand. 1931

1931First Japanese-made rapid filtration system for water supply

While developing our Pumps Business, EBARA considered the development of water infrastructure in preparation for disasters, leading to the completion of a water treatment plant, and contributing to the development of Japan.

1938

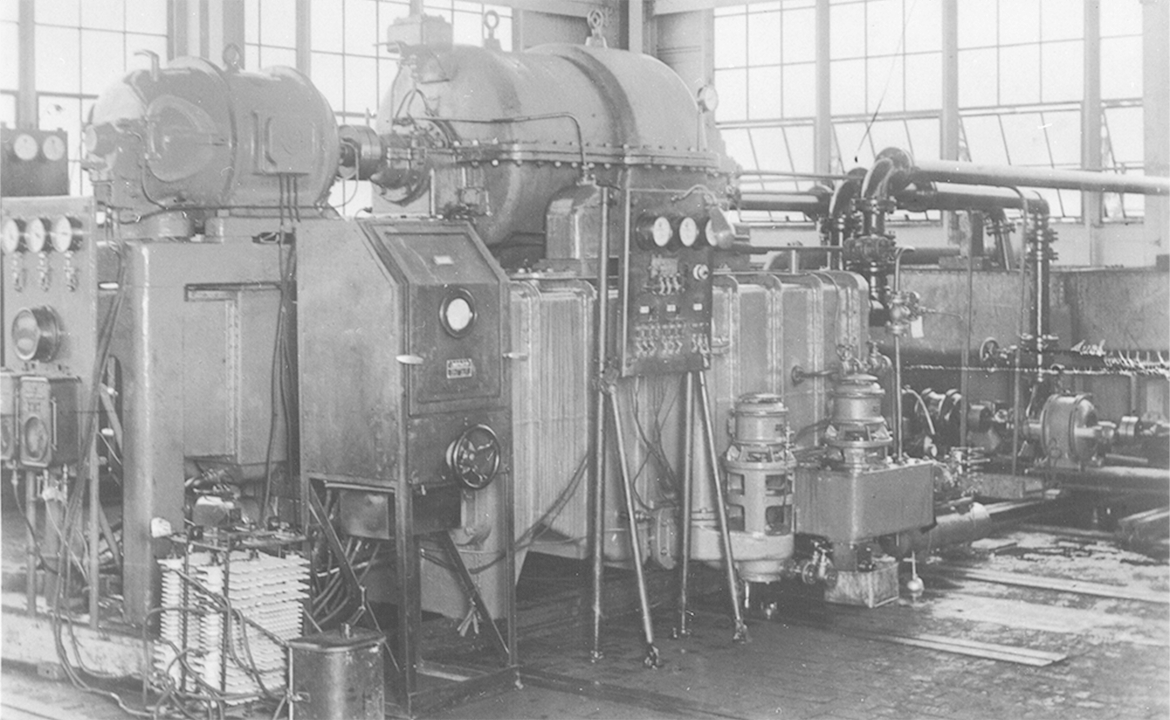

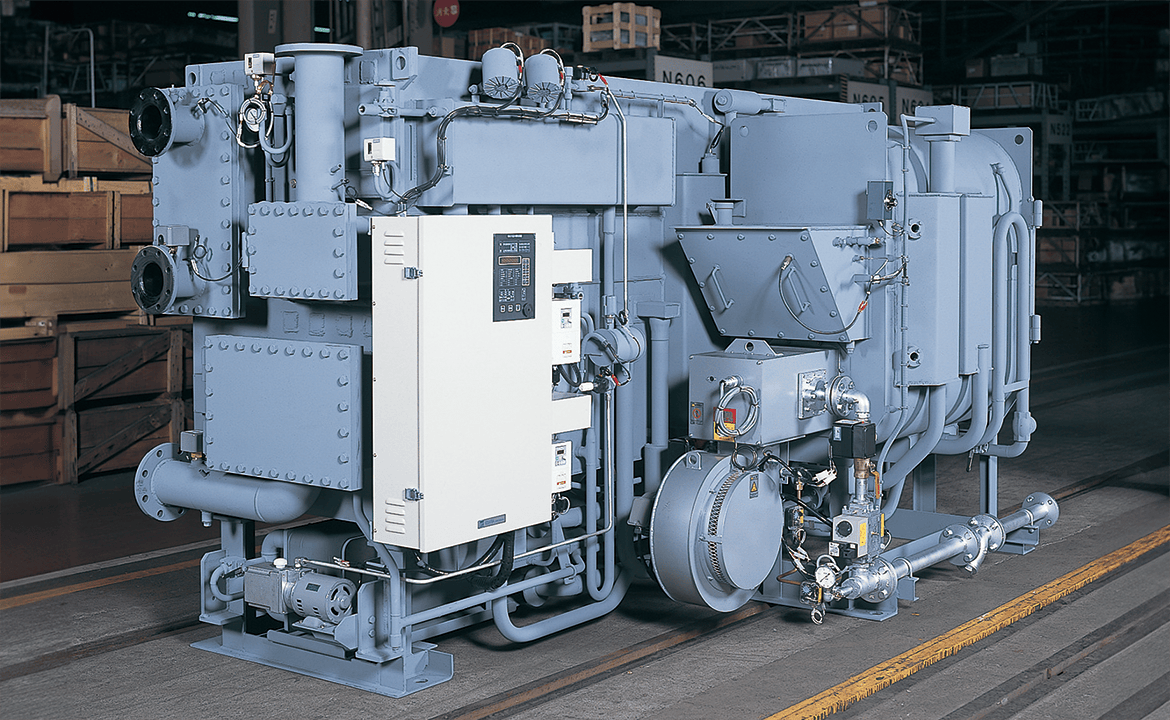

1938Our first large compressor, the largest in Japan at the time

This was a compressor turbine, a type of turbomachinery.

Although it was our first large-capacity compressor, its performance was superior to that of imports, and it became a regular feature in our lineup.

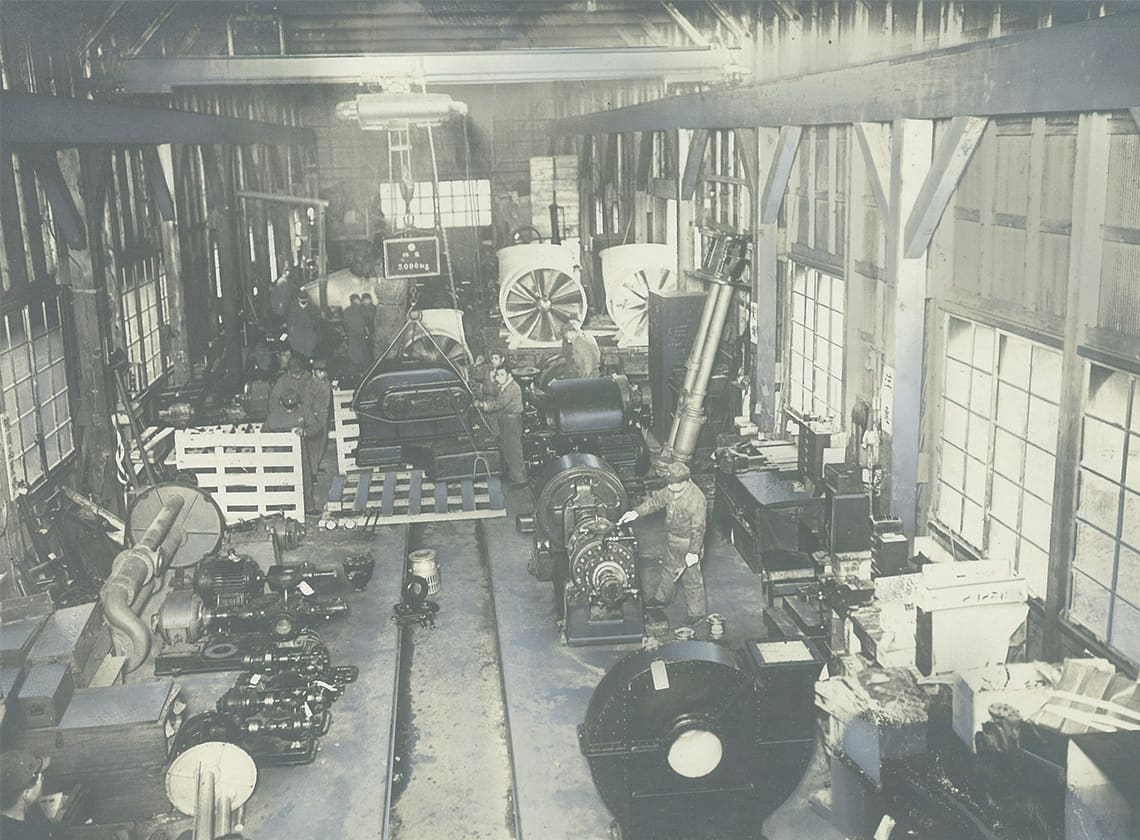

Supporting postwar reconstruction and rapid economic growth

EBARA worked hard to improve its technical capabilities and improve its production systems for pumps and fans.

It would play a key role in Japan's postwar reconstruction and infrastructure development during the nation’s period of rapid economic growth.

To make up for the technological delays caused by the war, the company aggressively adopted new technologies and eagerly developed its own products.

- See our products and activities

-

1956

1956Launch of sales of new concept standard pumps

Until then, we had supplied large-scale custom-made pumps for plants and facilities, but as the economy expanded, demand for pumps for households accelerated.

We developed a standard pump to capitalize on the then-new concept of mass production and sales. 1961

1961Entering the waste treatment plant business to solve the waste problem

With the development of business and industry, large amounts of waste became a problem.

We entered the waste treatment plant business by supplying the first stoker-type waste incinerator. 1963

1963Received order for our first absorption chiller using plant steam

Japan’s rapid economic growth led to the start-up of numerous plants, many of which emitted steam.

During this period, we received our first orders for absorption chillers, chillers that make effective use of steam in their operation. 1968

1968Going global in technical alliance with Elliott Co. of the US

Focusing on industries that would generate synergy with our Pumps Business, we entered into a technical alliance with Elliott Company of the US.

We further expanded our oil refining and petrochemical compressor business, seizing the opportunity to expand overseas. 1977

1977Delivery of first fluidized bed incinerator for municipal solid waste to solve the waste problem

The number of items that could not be burned in stoker-type waste incinerators, launched in 1961, increased as society developed.

We therefore delivered fluidized bed incinerators, which have a higher temperature and greater efficiency than stoker-type incinerators.

Contributing to the development of the information society

The Japanese economy was facing inflation and recession due to both the strong yen and the oil crisis.

Despite this, increased public investment in social infrastructure due to counter-recessionary measures provided a tailwind for EBARA's performance.

However, the subsequent sharp rise in the yen following the Plaza Accord dampened EBARA's appetite for exporting.

We began to tackle the next growth areas such as precision machinery, electronics, and the environment.

- See our products and activities

-

1985

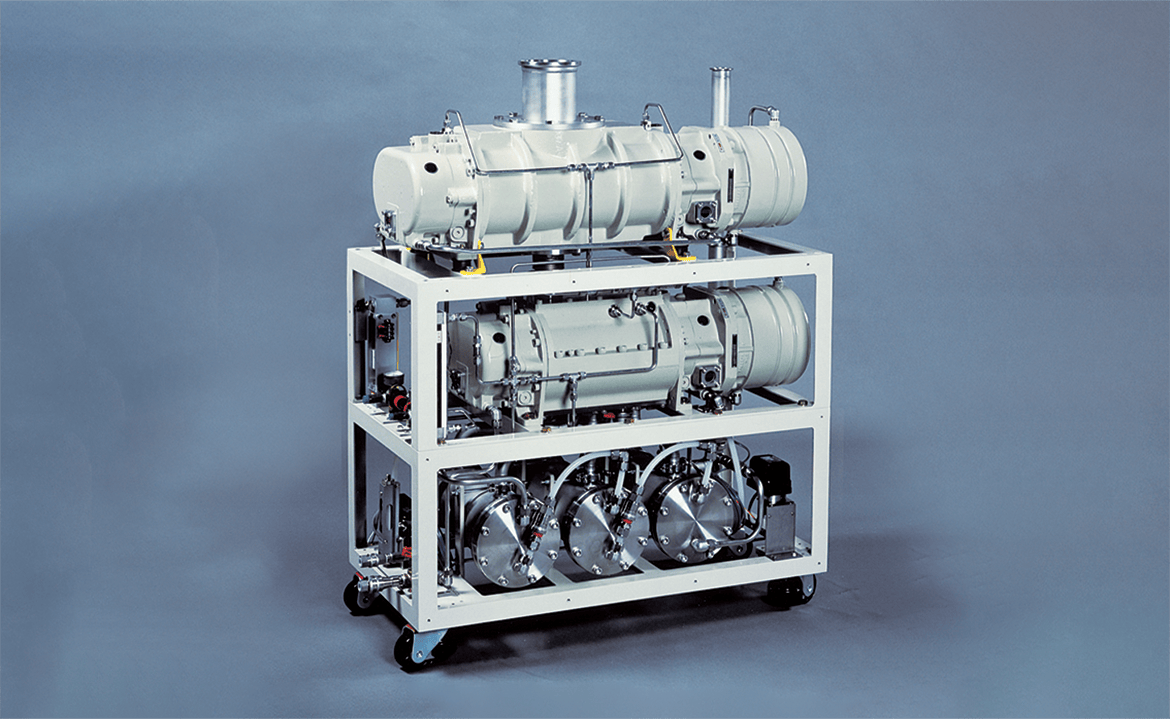

1985Start of the Precision Machinery Business

There was an acceleration in the enhanced performance and miniaturization of semiconductor devices.

Utilizing pump technology acquired in our Fluid Machinery & Systems Business, we developed vacuum pumps for semiconductors.

The following year, 1986, we delivered the first Roots type dry vacuum pump. 1987

1987Sales of absorption (dry) gas abatement systems for detoxify harmful gases

We developed gas abatement systems to detoxify harmful gases generated in manufacturing processes, such as greenhouse gases and toxic gases, and solve ongoing environmental problems caused by harmful emissions.

1992

1992Delivery of first CMP Systems to keep pace with ongoing modernization

EBARA began its development of CMP systems to support the miniaturization and multilayering of semiconductors, allowing for ever smaller electronic devices and plant machinery.

New Challenges

for a Sustainable World

In recent years, we have concentrated on growth areas, building a foundation for future development by developing and strengthening our global network, constructing the Futtsu Plant as our mother plant (completed in 2010), and expanding the Precision Machinery Company's plant.

We are also focusing on the development of new products and services that contribute to solving social issues by advancing fluid technology.

Looking to the future, EBARA aims to be an industrial machinery manufacturer that meets the needs of the world, repeatedly reforming and challenging ourselves in response to societal change.

- See our products and activities

-

2020Circular economy

2020Circular economyBusiness alliance for the production of structural proteins

We have partnered with Spiber Inc. to develop a large-scale manufacturing process for structural protein materials.

We improve the efficiency of structural protein production and apply the produced structural proteins to our products enhancing their functionality. 2020Sustainable seafood

2020Sustainable seafoodAiming to provide sustainable aquatic products using closed-loop circulatory systems.

In the field of smart aquaculture (aquaculture environment management using ICT), we are working to build a closed-loop land-based aquaculture system and services by utilizing our fluid and heat related technologies.

By maximizing our value proposition in combination with the technologies of our partners, we aim to create a world where people can continue to eat delicious fish in a sustainable manner. 2020Carbon neutrality

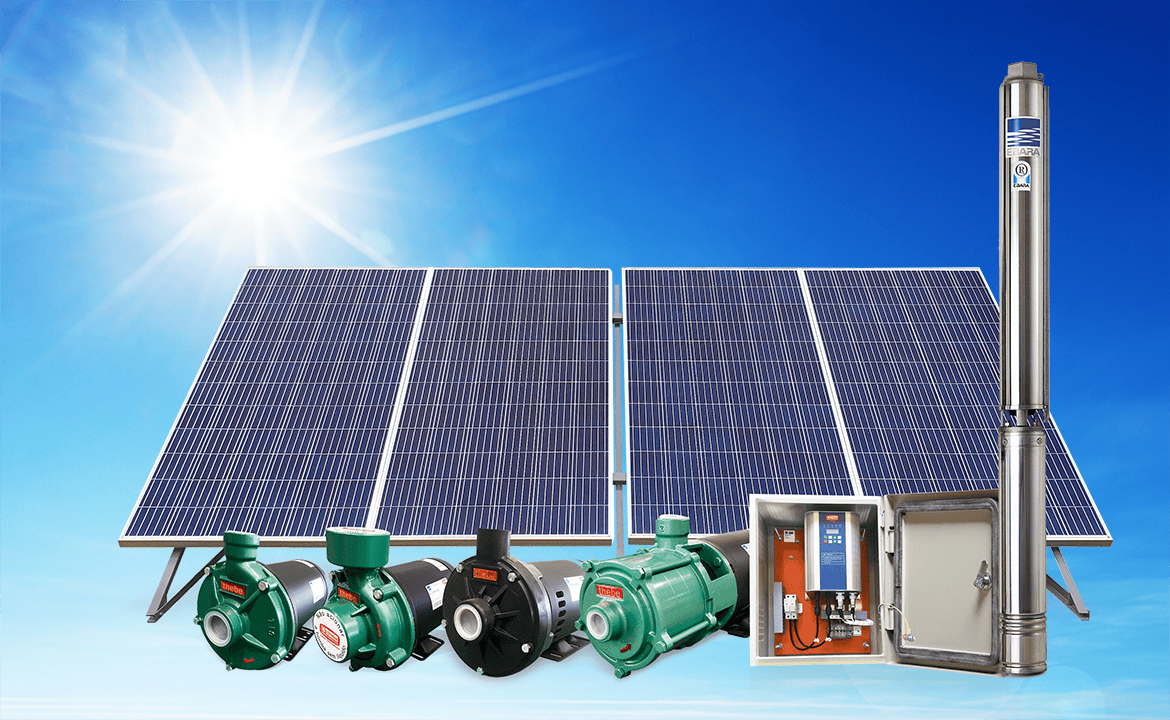

2020Carbon neutralityLaunch of solar pumps in Brazil

Our solar powered pumps are used to meet everyday needs such as securing drinking water in areas where there is no electricity.

They are also energy efificient, contributing to the reduction of greenhouse gas emissions. 2021Population growth, water shortages, food shortages

2021Population growth, water shortages, food shortagesSupporting water supplies in Kenya to bring water to 600 million people

EBARA Pumps Europe S.p.A. has signed a sponsorship agreement with Boreal Light GmbH in Germany to support its drinking water supply business in Kenya and contribute to the realization of a sustainable society.

2021Population growth, food shortages

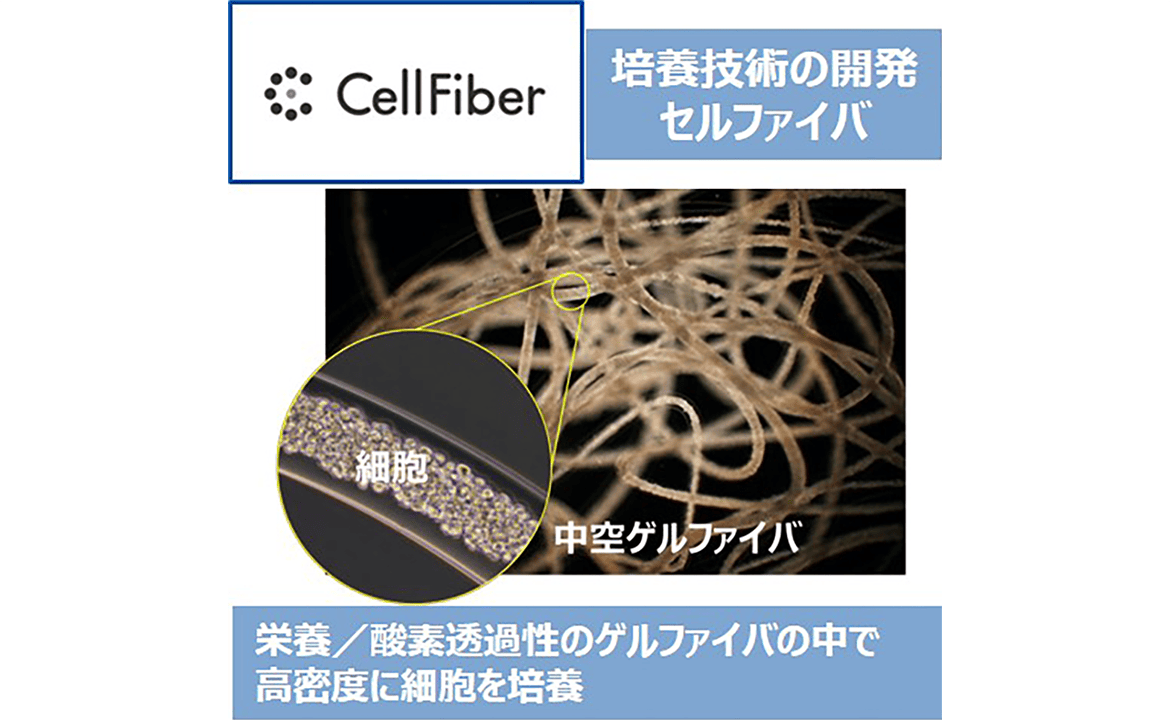

2021Population growth, food shortagesPushing forward cellular fiber and cellular agriculture business

We have partnered with CellFiber Co., Ltd. to develop a cell encapsulation system for manufacturing "cellular fiber".

We are working to improve the manufacturing process, stabilize the quality of the fiber, and accelerate the development of the cellular agriculture business. 2022Carbon neutrality

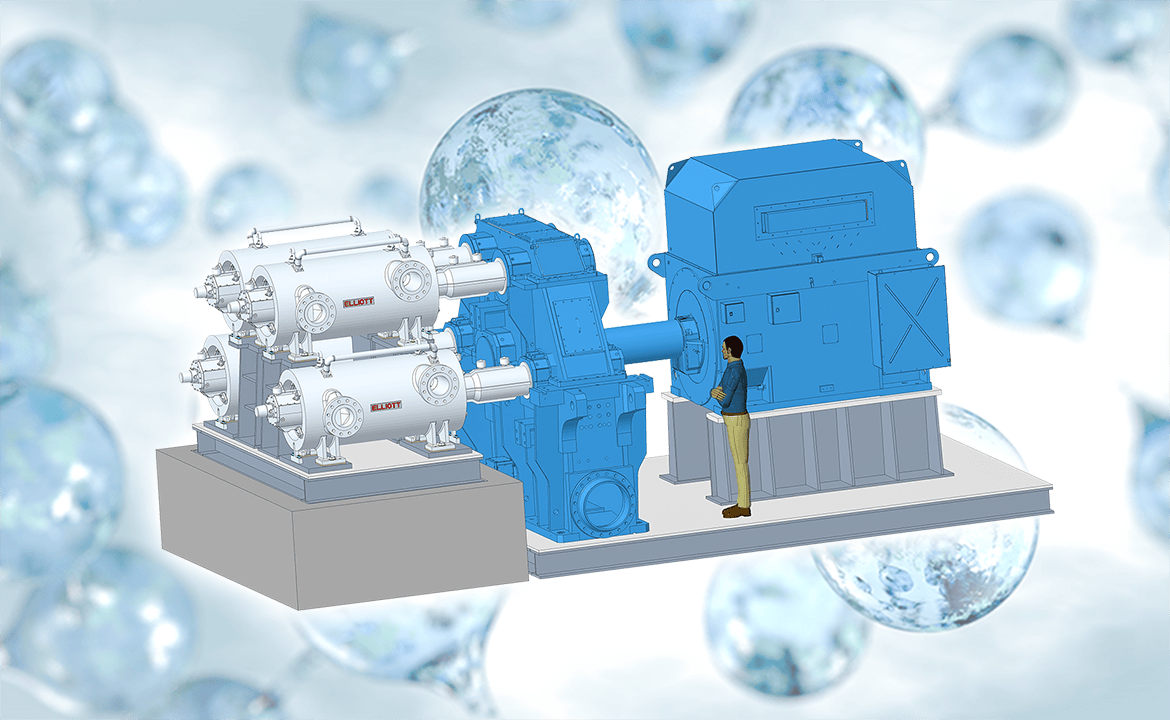

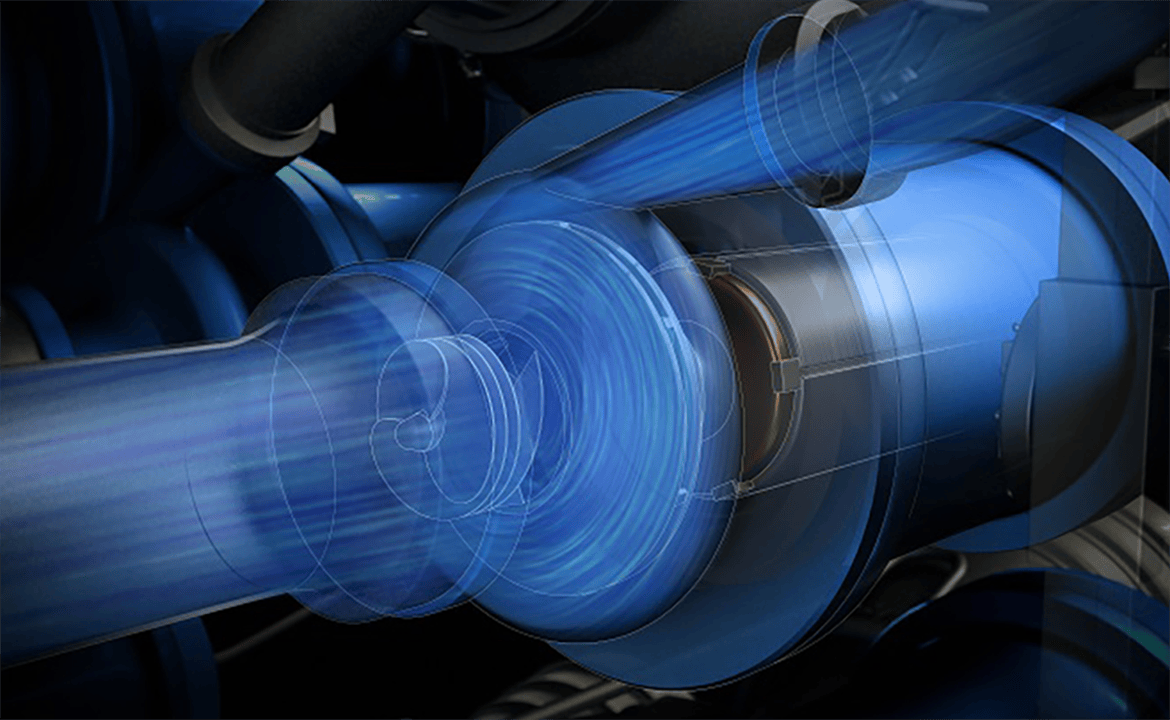

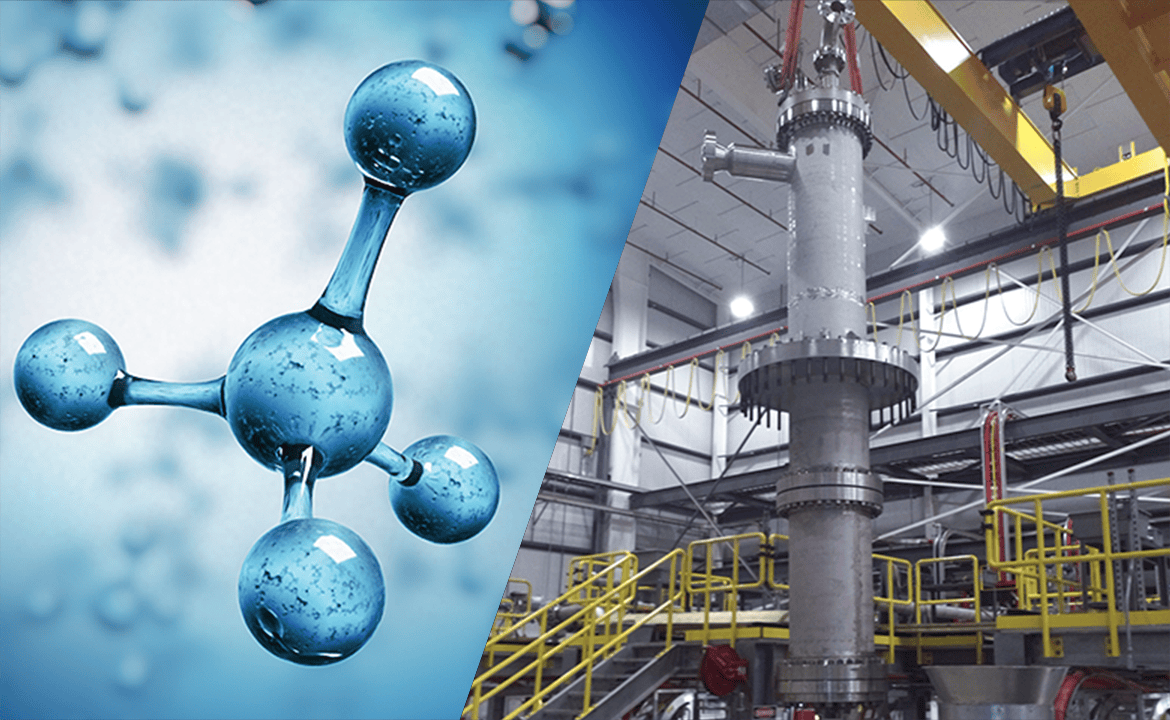

2022Carbon neutralityDevelopment of hydrogen compressor (Flex-Op)

Ebara Elliott Energy has developed a flexibly positionable compressor to improve operational flexibility in hydrogen compression.

2022Space business

2022Space businessDevelopment begins on electric pumps for rocket engines

The EBARA Group has started development of electric pumps for rocket engines for full-scale commercialization in the future, utilizing our extensive knowledge of rotary machinery technology to help improve electric pumps for rocket engines and enhance means of transportation.

2022Carbon neutrality

2022Carbon neutralityDevelopment of carbon dioxide-free hydrogen production technology

We are developing a turquoise hydrogen production technology that produces hydrogen from hydrocarbons contained in biogas and other materials without generating carbon dioxide, using a continuous cyclical process of methane dry reforming, hydrogen separation, and carbon capture.

2023Carbon neutrality

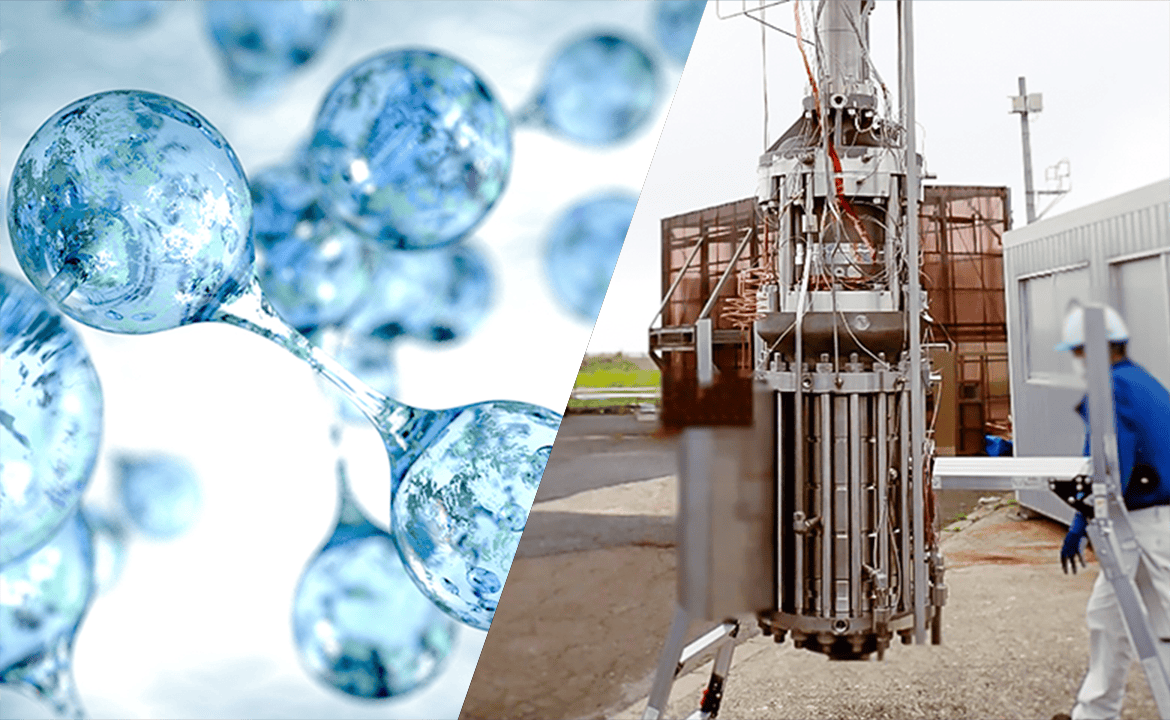

2023Carbon neutralitySuccessful development of the world's first liquid hydrogen booster pump

Leveraging EBARA's strengths in high-pressure centrifugal pumps and cryogenic technologies, we have developed the world's first liquid hydrogen booster pump, for use when liquid hydrogen is unloaded from the tank and supplied to a hydrogen gas turbine.

2023Population growth, food shortages

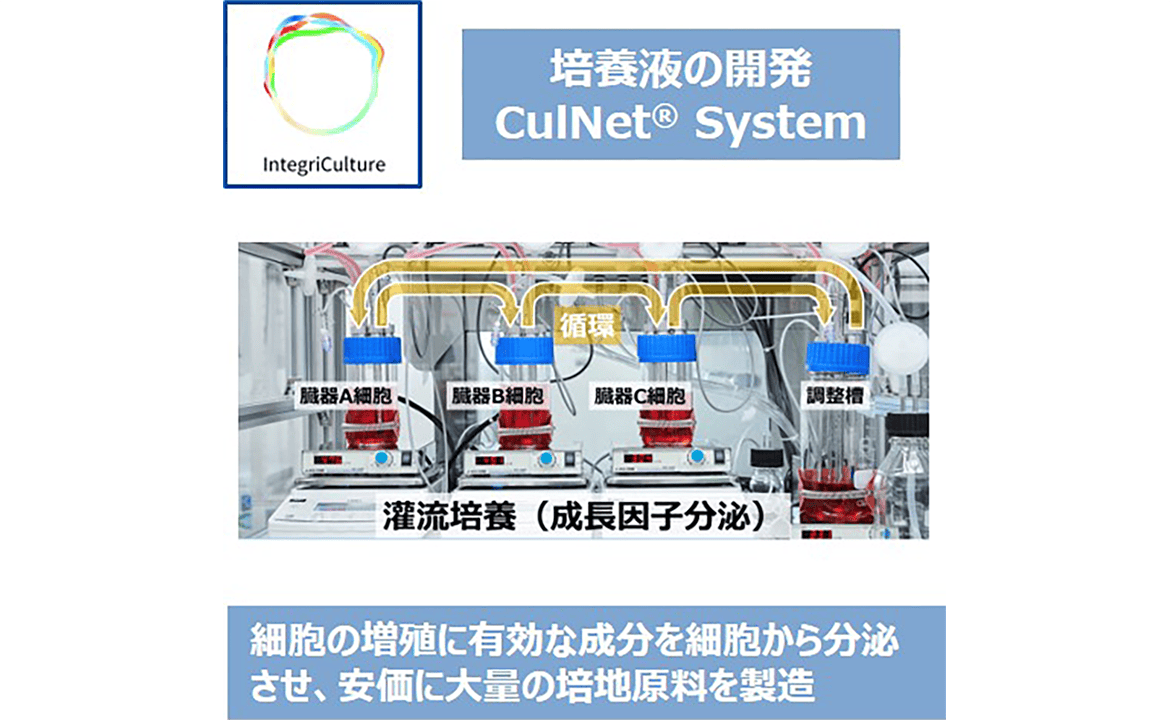

2023Population growth, food shortagesLaunch of joint development with IntegriCulture on cell culture technology

We have partnered with IntegriCulture Inc. to scale up the "CulNet System®", a general-purpose large-scale cell culture technology.

We will apply our expertise in fluid control technology and equipment design to the development of cell culture equipments for the cell agriculture business. 2023Population growth, food shortages

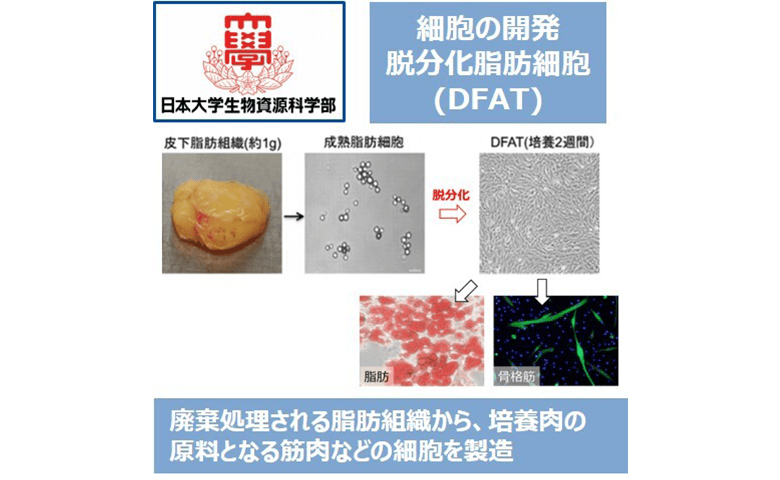

2023Population growth, food shortagesLaunch of joint research with Nihon University to eliminate global food shortages

We have launched a collaboration with the College of Bioresource Sciences at Nihon University to apply dedifferentiated fat cells (DFAT) as a stable cell source in cellular agriculture.

We will apply our expertise in fluid control technology and equipment design to the development of large-scale culture equipments for DFAT. 2023Carbon neutrality

2023Carbon neutralityDevelopment of canned motor pumps for liquid ammonia

Adopting a structure in which the motor section is submerged in liquid ammonia makes it possible to transfer the ammonia liquid without leakage to the outside.

This will help to transfer ammonia solution more safely. 2023Carbon neutrality

2023Carbon neutralityDevelopment of the world's first hydrogen-fueled absorption chiller-heaters

By using hydrogen as a fuel, these chillers can be operated without any CO2 emissions by fuel combustion.

They are also able to “use” hydrogen directly without converting it into power or electricity.

EBARA enivisions a future where hydrogen replaces kerosene, gasoline, and city gas around the world.