Infrastructure Company's Strategic Table of Technological Capabilities

The EBARA Group has reorganized into five in-house companies to handle each of its target markets.

Accordingly, we revised the EBARA Group Strategic Table of Technological Capabilities to show the core technologies that constitute the competitive edge of each of the five in-house companies, the shared technologies between the companies, and the common basic technologies.

We will utilize these technologies to contribute to society with passion and dedication.

Planning & Proposal

EBARA possesses the technology to plan and suggest facilities that can create optimal effects and value for the community, by meeting the needs of our customers, who are mainly government agencies, right from the planning stage. EBARA provides one-stop services from system proposal to design (mechanical and electrical), procurement, construction (construction management), and after-sales services to collectively solve a wide range of issues.

Project management

EBARA possesses comprehensive management expertise to control projects from planning to implementation, design, and completion of facilities, such as drainage pumping systems for infrastructure.

Construction management

EBARA possesses construction management expertise to carry out projects and achieve goals by managing processes, quality, and safety, and controlling costs for new construction, expansion, and renewal of infrastructure plants.

Power transmission device

EBARA has developed machinery technology for connecting drive equipment such as motors and turbines with pumping machinery such as pumps, fans and compressors.

Quality assurance

EBARA possesses technology to control the quality of plants, including all installed equipment. EBARA also possesses the technology to perform various types of inspections on the performance and functionality of a variety of products.

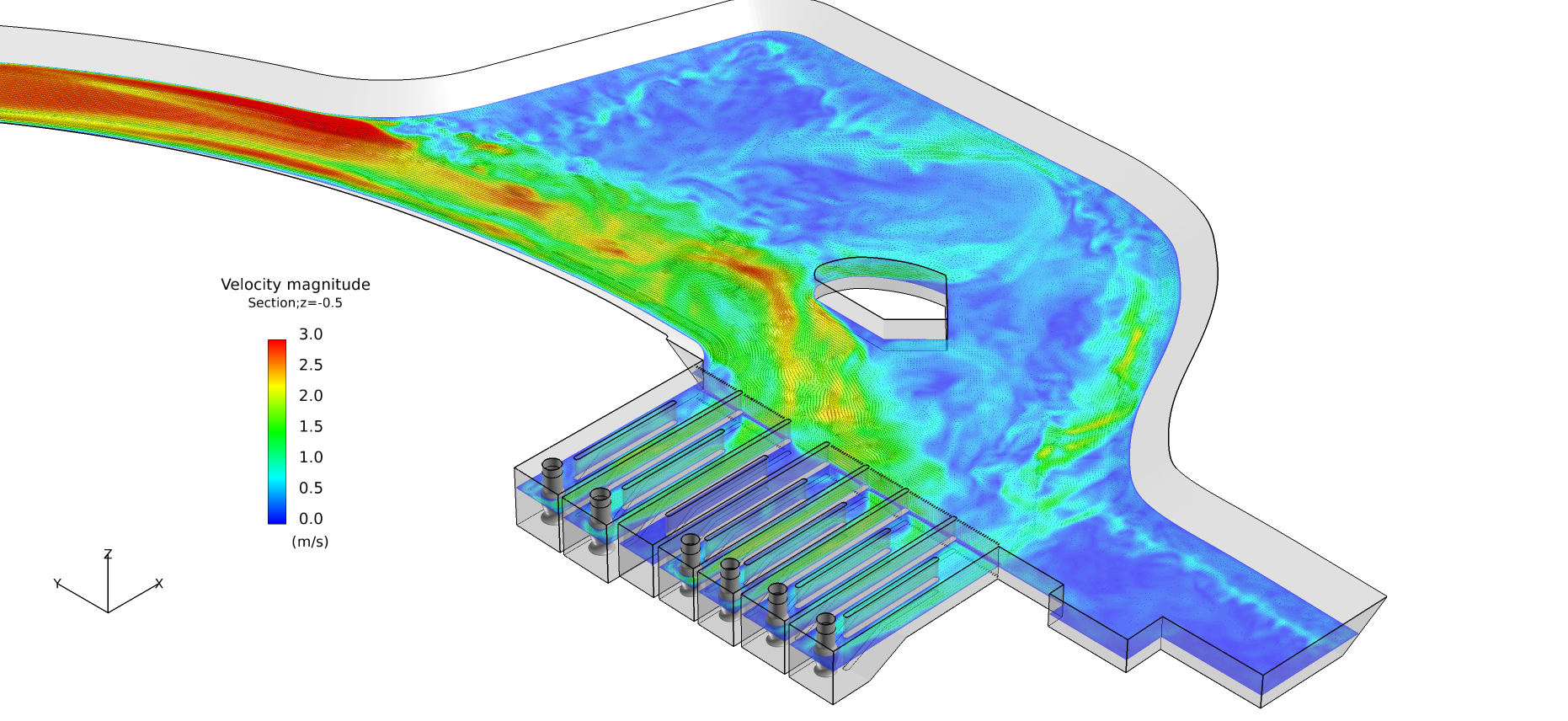

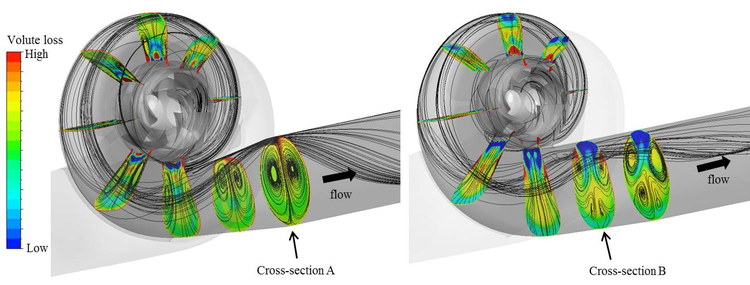

Fluid

EBARA possesses numerical analysis technology applicable to fluid transient phenomena (water hammer, pulsation, vortex, etc.) that occur in pump plants, as well as countermeasure technologies for dealing with such phenomena.

Maintenance

EBARA possesses the maintenance technology to properly maintain the functions and conditions of the various equipment and facilities that make up plants. EBARA ensures that facility functions are kept in optimal condition through inspection, diagnosis, and repair techniques when deterioration or other problems are detected.

Electrical Instrumentation

EBARA possesses technology for electrical design of power receiving and distribution equipment and power generation facilities for infrastructure plants, as well as for designing corresponding monitoring and control systems.

Bearing Technology

EBARA possesses technology for the bearings used to support rotors in rotating machinery such as pumps and fans. These bearings are divided largely into rolling bearings and sliding bearings. In particular, EBARA has developed proprietary technology for submerged sliding bearings and hydrodynamic bearings.

Vibration & Acoustics

EBARA possesses technology to suppress and reduce the impact of vibration and noise, and realize an appropriate operating condition to counter the various vibrations produced by parts such as rotors, casings, and fluid-related systems in rotating machinery such as pumps and fans. In a broad sense, this also includes fault diagnosis (remote monitoring systems) and various sound- and vibration-proofing devices.

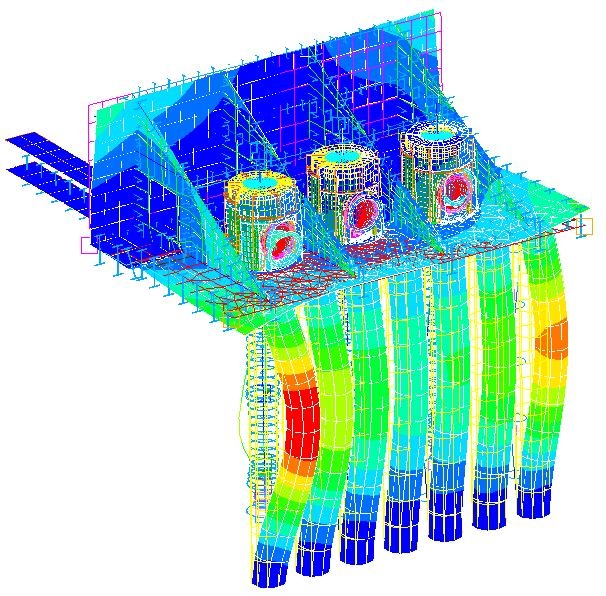

Structural Design

In order to realize high reliability and long life for pumps and compressor products, EBARA has developed technology to appropriately evaluate strength and deformation even in harsh operating conditions such as under high pressure.

Numerical Analysis

In order to improve the performance and reliability of rotating machinery such as pumps and fans, and of pump stations, EBARA has developed systems and proprietary technology for applying numerical analysis such as oscillatory structural mechanics and thermal hydraulics.

Fluid Machine Design

EBARA possesses technology to develop and design the aerodynamic and hydraulic components of our turbomachinery products such as pumps, compressors, fans, and steam turbines by utilizing advanced CAE technology such as flow analysis and optimization technology.

Digital Engineering

This group of technologies maximizes development throughput by identifying simulation processes necessary for various product development needs, and includes technologies for automating and streamlining Computer Aided Engineering (CAE) from 3D modeling to flow analysis, and vibration and structure analysis.