Issue No. 255〔Discussion Meeting〕

Symposium Ebara Research System

−Cooperation between Research and Business to Create a New Future−

Interviewees

Hirokuni HIYAMA*

Hiroshi SOBUKAWA**

Akira GOTO***

- *

- Technical Superintendent of Technologies, R&D Division, Doctor of Engineering, Visiting Professor of Kyushu Institute of TechnologyWhen Hiyama joined the company, he started working on product designing and development for the Elliott Machine Division. In 1979, he was transferred to the Research Laboratory. After the dissolution of Ebara Research Co., Ltd., he has become a driving force for Ebara Open Innovation and Ebara Open Laboratory in the Technologies, R&D Division of Ebara Corporation.

- **

Division Executive of Technologies, R&D Division, Division Executive of Advanced Technology Division, Precision Machinery Company

When Sobukawa joined the company, he started working on product designing and development of Precision Machinery Company. After 2017, he serves as Division Executive of the Technologies, R&D Division and concurrently supervises the Ebara Open Laboratory

- ***

Technical Superintendent of Technologies, R&D Division, Doctor of Engineering

When Goto joined the company, he started working in the Research Laboratory (later the Ebara Research Co., Ltd.) In 2005, he was transferred to the headquarters and engaged in planning of new technologies. After 2006, he fostered technology development at the Fluid Machinery & Systems Company. Until the dissolution of Ebara Research Co., Ltd., he concurrently worked for Fluid Machinery & Systems Company and Ebara Research Co. After 2017, he has been providing support for the Ebara Open Laboratory at the Technologies, R&D Division as Technical Superintendent

Ebara Corporation has established and operates a unique research system called Ebara Open Innovation and Ebara Open Laboratory. In this article, we asked key personnel about the present research system, which is already engaged in new challenges, and the vision of its future.

What is Ebara’s unique research system?

Interviewer: Tell me about the new research system of Ebara Corporation (hereinafter referred to as Ebara) that seems to be achieving successful results through unique measures?

Hiyama: The Ebara Corporation headquarters and three of our Companies, namely the Fluid Machinery & Systems Company, Environmental Engineering Company, and Precision Machinery Company supervise their respective businesses, and product development is carried out by each Company. Ebara Open Laboratory (EOL*1) was launched in 2014 as a research facility of Ebara Group (Figure 1) and has been conducting researches on fundamental technologies of various products. Many of the EOL researchers conduct researches in addition to holding positions in one of these three Companies. In other words, an engineer of the Company conducts research at EOL on a theme related to a product developed by the Company while they engage in product development of their Company.

Fig. 1 Main organizational structure of EOL

*1: Ebara Open Laboratory (EOL)

This research facility of Ebara Group was launched in 2014. As a research facility of Ebara Group with an open innovation environment, many EOL research members concurrently serve as designers and engineers of each Ebara Group Company.

Interviewer: We have a stereotype image of a company's research laboratory. The laboratory is disconnected from the product development, production, and management sides of the company, and researchers are totally immersed in their own pursuits.

Hiyama: In the past, there was a research and development style called the linear model. All processes starting from fundamental studies and application studies to development, designing, and manufacturing processes are carried out one after another within one company and then the product is introduced and sold in the market. Today, it has become difficult to handle all the processes within one company, since the products have become more complicated, the speed of technology innovation has become significantly faster, and the product life has become shorter. In the US, an upsurge in the emergence of startup companies created conditions where the key to new technology development is how a manufacturer can acquire the technologies of these startup companies. The days of researches conducted within an independent research laboratory were over.

Even Ebara Research Co., Ltd. became unsuitable as a research system for the times and had to be dissolved in 2009. We looked for a new research model based on the previous system, which ultimately led to the establishment of the present form of EOL.

Interviewer: The dissolving of Ebara Research Co. seems to be quite a drastic action, wasn't it?

Sobukawa: When the old laboratory was dissolved, I was working at the Precision Machinery Company and was very surprised when I heard about it. Ebara Research Co. always contributed to our product development task when we developed a product that was technologically difficult to make, such as a magnetic levitated ultra-high vacuum pump or CMP*2 . The strength of our company is in technologies such as advanced fluid simulation and optimization as well as studies on rotor dynamics*3, cavitation*4, and materials. All of these technologies and studies were fostered by Ebara Research Co. until that time, which made me wonder whether it was the right move to dissolve this research laboratory.

Goto: Ebara Research Co. was a research laboratory that functioned as a completely independent organization from Ebara Corporation. For that reason, sometimes there was an inevitable gap between the objective of a research conducted by the research laboratory and objectives of the Companies that develop and sell the products. Since there was a considerable disconnect (or difference) between the research activities of the laboratory and the product developed by the Companies, the laboratory conducted fundamental studies assuming that these studies would yield results over the next five to ten years. The Companies, however, were faced with the immediate business challenges of today and tomorrow. Particularly, to meet the demands in overseas markets, it was necessary to develop a product even quicker than the timeliness required for meeting the demands in Japanese market. Needless to say, Ebara Research Co. had insufficient understanding of the business side and could not cope with responding efficiently to those requirements.

Sobukawa: From the standpoint of the Companies, their engineers often found it difficult to consult with the Ebara Research Co. because of the gap in understanding a situation. For example, even when a Company engineer went to the research laboratory for advice on solving a problem of a product through their superior, the laboratory seemed unable to provide any concrete suggestions. As a result, the engineer must have felt that the research laboratory was unresponsive because the problem was not addressed in spite of the immediate need for a solution.

Goto: When the company was founded, the engineers served as both researcher and product developer and had an understanding of the business side of the entire company. As the division of work became more marked, the gap between research laboratory and the Companies most likely became wider.

Hiyama: Under these circumstances, it was decided to dissolve the research laboratory and look for a new and more efficient research model.

Sobukawa: After Ebara Open Laboratory was set up in its present form, the gap between the laboratory and the Companies has become smaller. I believe that, after the dissolution, the transfer of the researchers to the Companies has made the situation better.

Goto: The best thing for the researchers is being able to introduce their research to the world. If researchers only stick to working on their research in an isolated laboratory for extended periods, they fail to understand how their research could be introduced to the world. Because the researchers joined the Companies, they now know how to make their knowledge useful for the business side. Ebara Open Laboratory has succeeded in bringing about this significant change.

*2: CMP stands for Chemical Mechanical Polishing (or Planarization). This technology planarizes a surface by performing mechanical polishing and chemical polishing simultaneously using abrasives or abrasive fluids that have chemical actions.

*3: Rotor dynamics. Rotor dynamics is the dynamic characteristics of a rotating machine such as a pump and turbine.

*4: Cavitation. Cavitation is a phenomenon where air bubbles are produced and vanish in a repeated cycle when a fluid boils after the pressure of the fluid drops during flow. Cavitation causes a pump to become unstable.

Period during which the formation of a new research laboratory was being considered

Interviewer: You mentioned that the research laboratory was dissolved. That means there was a period when Ebara did not have any research facility, right?

Hiyama: Most of the researchers were assigned to the Companies and engaged in various types of jobs such as product development, designing, material procurement, and development of manufacturing technologies.

However, both the management of the company as well as the engineers knew we needed a system that could serve as a research laboratory. We were looking for a new research model.

We have a council called the Research & Development Committee that mainly formulates medium- and longterm research and development strategies of the entire Ebara Group and approves the researches to be conducted using the corporate budget. The Committee continued to be relevant even after the research laboratory was dissolved. One year from the dissolution of the previous laboratory, the Research & Development Committee approved a research budget of 15000000 yen to start Ebara Open Innovation (EOI)*5. To put it simply, EOI is a research model that allows conducting joint research with external research institutions such as universities. In the case of EOI, a person in charge of a research project is selected from personnel of Ebara’s business divisions along with a researcher from external research institutions and the corporate budget is used for research expenses. In the initial stage after EOI has started, Ebara has taken up the tasks of searching for research partners, drawing up contracts, setting meetings, and recording the minutes of these meetings so that business division personnel in charge of research project can concentrate on promotion of the project.

Mr. Tsujimura (Senior Managing Executive Officer) established the policy of “starting business on a small scale and growing it gradually,” which I think it is a great practice. Start with a small objective and develop it with care.

In reality, however, we had no research facility and no researchers. Actually, we wanted to call back the researchers of the old laboratory, but were unable to do so because they were already engaged in their work at the respective Companies. Therefore, we decided to start EOI activities on only five research projects by collaborating with external research institutions.

The professors at the universities were eager to learn about the needs of the industrial sector and indicated their willingness to work with us. In the first year after the launch of EOI, we consulted with Mr. Goto about research themes and he suggested five themes that were being studied in collaboration with a university among those related to the Fluid Machinery & Systems Business.

Goto: I selected themes such as cavitation and seawater corrosion that are core technologies of the Fluid Machinery & Systems Business and must be continued unconditionally.

*5: Ebara Open Innovation (EOI).

Research platform started in 2010. This facility is used for collaborative research work between Ebara’s researchers and Japanese and overseas research institutions in open environments beyond the borders of organizations.

Interviewer: Tell me about the successful cases of fundamental studies that were started up under such conditions.

Goto: A huge vertical-shaft pump is used for pumping out a rapid flow of rain water caused by a sudden guerilla rainstorm in cities or for supplying a large volume of seawater to plant facilities. These applications demand an increase in the operation speed and the use of bearings that are resistant to wear. These requirements, however, increase the risk of vibration trouble.

I recognized this problem also when I went to a pumping site in the Middle East. Over there, other competitors were also having the same problem regarding vibration. They were trying to control this problem by providing reinforcement or maintenance for the foundation as a support measure.

Therefore, we started a joint research with the university’s laboratory in order to study this nagging problem from the basics and find a solution for the root of this problem. As we continued our studies, we were able to clarify the wear mechanism of the bearings and constructed the vibration theory of a vertical rotor system. Through these efforts, we improved the wear resistance of the bearings and were able to reinforce the vibration resistance and stability of vertical-shaft pump (Figure 2) in a comprehensive manner.

Fig. 2 Examples of successful fundamental studies

Interviewer: So can we assume that EOI successfully improved various aspects of a pump as a result of the studies the basics?

Hiyama: From the second year after the launch of EOI, we also selected research themes among the ones implemented by the Precision Machinery Business. Since the research activities of EOI were started from scratch, I thought it is a good idea to formulate technologies by pooling wisdom from all over Japan from that time.

For instance, the Precision Machinery Business has a big research objective known as CMP. A semiconductor wafer (semiconductor substrate) is polished mechanically and also using abrasives that produce a chemical action in order for its surface to be planarized. This process is called Chemical Mechanical Polishing or CMP process. To start the research on CMP, we invited university professors who were continuously engaged in researches in Japan to joint research projects with us and purposefully tried to win over young professors in particular to our side.

In one of the cases, we invited a university professor, who was conducting research on the measurement technique of the potential in a cell to work on the application of his research to the technology for measuring the potential of a wire in the fluid of a semiconductor integrated circuit.

Sobukawa: An abrasive used in the CMP process can cause some of the materials to corrode. We encouraged this professor to develop a technique for predicting the possibility of corrosion of a material by measuring the electrical conditions on a wafer using a microscope called atomic force microscope (AFM) that can measure an extremely small force. This research produced an extremely effective method for the actual CMP process development. This was one of the cases that demonstrate a successful achievement brought about by research.

Goto: Since we embraced the open innovation research model, it has been easier for us to incorporate researches in different fields.

Hiyama: In another example, we requested a university professor who specialized in fluids to study how water (fluid) droplets adhered on a wafer surface evaporate. Extremely small slurry particles adhered on a wafer surface are removed by after CMP cleaning process. In this process, if droplets remain on the wafer surface, oxygen enters the droplets and produces water marks that cause circuit defects. Furthermore, the drying phenomena for droplets adhered on the edge and that for droplets adhered on the wafer surface are different when the spin drying process of a wafer is used.

So, we encouraged the professor to apply the visualization technique used for fluid machinery to observe the vaporization process in order to formulate an equation for the process. This is an example where the technology of a “macro” perspective is applied to a “micro” perspective. Once this equation is formulated, we can discover the optimal wafer cleaning and drying method and the environmental conditions to be complied with. As a result, this research can eventually contribute to semiconductor manufacturing (Figure 3).

In the third year, we selected the research themes among the ones implemented by the Environmental Plants Business. We now have a proven track record that shows that Ebara Open Innovation can produce great results even with small research expenditures. At present, researches on 50 themes are being conducted in joint projects with 32 universities and 56 laboratories.

There are, however, some researches that cannot be conducted using the EOI platform alone. First of all, we have confidential research projects that should not be disclosed to the outside and these projects cannot be handled by the EOI model. Also, if we always outsource our researches, we cannot foster new researchers within the company. There are also researches that can only produce results when they are conducted over a long period of time. To continue long-term researches, we need in-house researchers as well as a reliable research system. That was why we decided to set up a new research model.

Fig. 3 Examples of the application of technologies in different fields

Concurrent work program to support a new research model and inviting the public to propose research themes

Interviewer: That is how you came up with the present research system, right?

Hiyama: Yes, that’s right. Ebara Open Laboratory (EOL) is our present research system. We established EOL four years after launch of Ebara Open Innovation (EOI) in 2010 when the achievements of EOI were being gradually recognized in the company. One thing that we had to make sure was that EOL should not operate in the same way as the dissolved Ebara Research Co., Ltd.

Interviewer: It was a difficult task, wasn't it? Did you create a new framework?

Hiyama: We created roughly three frameworks. As I mentioned earlier, the first framework is for researchers to bring in the research themes and work for EOL while concurrently performing their business tasks at their respective Company so that we can follow the policy of “starting business on a small scale and growing it gradually.” For the second framework, we set up three research sections, namely the Fundamental Technologies Research Department, Product Core Technologies Research Department, and Advanced Analysis Department. As the third framework, we introduced a mentoring program. We ask a person in charge of technologies and development of each Company who has practical experience at the Company as well as research experience to serve as a mentor to provide guidance or advice on a research to the researchers of each Department.

When we designed the frameworks of EOL, we particularly aimed at achieving good results quickly with greater emphasis. For example, we select several themes that can bring about good results quickly as a key objective and concentrate on these themes so that it can lead to strengthening the competitive power of a product. We also make sure that the researches of EOL will be as open as its name declares. In other words, we aimed at forming a research facility that is open to the company as well as to the outside of the company. That is why we created a platform that enables inhouse personnel to bring in their research themes and assemble and collaborate with researchers of outside organizations in an open innovation environment.

Interviewer: How do you decide a research theme?

Hiyama: When we started the Ebara Open Laboratory, we created a platform to collect research themes from the entire Ebara Group. We collect research themes from the personnel of the Companies. We collect ideas, such as existing problems or research that a person wants to conduct. Those ideas are examined and actual research of the selected themes is conducted by the person who suggested this idea. This is how this model works. Although research can be conducted in the Company, it becomes difficult to cope with the research unless results are achieved quickly. So, naturally, themes that can not achieve quick results are proposed as much as possible.

A management staff is available at EOL to provide support to researchers so that they can achieve results quickly and bring the results to their Company to apply them for business.

Interviewer: So you say the distance between the Companies and laboratory became closer because researchers are going back and forth between the Companies and laboratory.

Sobukawa: We hold a progress report meeting on research themes once every two weeks. Any personnel of Ebara Group can participate in this meeting to learn about the themes that their business is related to or themes that they are interested in. Such meetings are also effective in bringing the laboratory researchers and the Company personnel closer.

We also hold a research presentation of Ebara Open Laboratory once a year. Along with short presentations of all research themes, we also conduct a poster session (Figure 4). Anyone can ask questions about a research with a person in charge of that research in front of a poster. You can talk to designing and development personnel so that you can establish ties with researchers in different fields as well. I think these events are producing very good effects.

Fig. 4 Poster session of research presentation

Interviewer: Are there full-time researchers at the Laboratory?

Hiyama: Yes, there are full-time researchers. As a matter of fact, we are increasing the number of fulltime researchers in phases at the moment. We are hiring new researchers too. There are some tasks that can be only done by full-time researchers. We have high-level experts for the fundamental technologies, which are very important for product development. While these experts conduct long-term researches to enhance these technologies, they also develop younger researchers. Full-time researchers are in charge of these tasks.

Conducting research by collaborating beyond the boundaries of business fields

Interviewer: Has the working environment at the laboratory changed in the new research model?

Sobukawa: One of the most noticeable changes is that the new laboratory provides us with a sense of unity and bonds that tie the Companies and EOL. Since personnel of the Companies are dispatched to EOL to conduct researches, the Companies can obtain information on personnel conducting researches as well as information on a research itself. On the other hand, EOL can obtain information on personnel developing a new product as well as information on the developed product itself. Now, we have a clear view of the relationship between the laboratory side and the product development side. As a result, it is now possible to have collaboration beyond the boundaries of the Companies and expand the applications of obtained technologies to other fields.

Interviewer: Tell me about specific successful results of the new research model.

Goto: For example, there is a case where technology owned by the Fluid Machinery & Systems Company was applied to a product of the Environmental Engineering Company (Figure 5).

Fig. 5 Example of horizontal expansion of advanced fundamental technology

The Fluid Machinery & Systems Company possesses advanced technology for optimizing the design of pumps. Optimization means to find the best design of a pump based on various customer requirements. When a pump is developed, there are requirements such as high pumping efficiency, high pumping stability, and low pressure when the discharge port is closed. These performance requirements involve trade-offs. Since all the requirements cannot be complied with, we must seek out the best balance among them. That is the technology of design optimization. We applied the technology developed by the Fluid Machinery & Systems Company to the design of grate-type incineration of waste treatment plant developed by the Environmental Engineering Company. For the designing of an incinerator, it is necessary to improve the incineration efficiency and at the same time reduce emission gases such as nitrogen oxides and carbon monoxide, which are in tradeoff relationship. It has been revealed that the technology developed by the Fluid Machinery & Systems Company is very effective in finding out an optimal incineration design for these conflicting requirements.

Sobukawa: The study on the temperature analysis simulation for a dry vacuum pump*6 conducted by the Precision Machinery Business is also on the right track. A dry vacuum pump is a vacuum pump used for manufacturing semiconductors and other applications. Since this pump exhausts a high-reactivity gas used for manufacturing semiconductors, it is necessary to maintain the temperature of a flow path at higher than a specific value so that gas does not become solidified in the pump. On the other hand, the clearance between a rotor and casing is designed to be extremely narrow in order to maintain the pumping performance. For that reason, when the temperature becomes too high, the rotor and casing will come into contact with each other. To prevent this problem, it is necessary to control the temperature of a flow path in the pump at the optimal level. However, it is very difficult to predict the internal temperature of a pump and therefore we actually make a prototype pump to check the temperature. If we can predict the internal pump temperature by means of numerical analysis, we should be able to complete development of the pump properly within a short time when the pump design is modified or process conditions are changed. We are expecting this technology to contribute significantly to the advancement of pump development. The research on this technology cannot be outsourced and therefore it was only possible to conduct at the Ebara Open Laboratory.

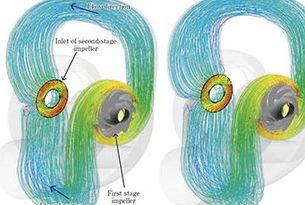

Goto: With regard to open innovation research, we worked on a joint research for solving the vibration problem of the vertical-shaft pump (mentioned earlier) with Japan Aerospace Exploration Agency (JAXA) after the Ebara Open Laboratory was launched. We were able to propose a new pump design that suppresses vibration by applying the morphological design of a rocket turbo pump (developed by JAXA) to industrial fields.

Generally, when a pump is designed, we decide the shape and placement of the impellers and flow paths first in order to maximize the efficiency and then we make a detailed design of the mechanical system. Because of that, if mechanical vibrations occur, we are not left with many options and the task of suppressing vibration becomes difficult. Therefore, we completely changed the way we approached the pump design process, and designed the pump with higher priority on pump stability first. Consequently, we solved the problem of pump vibration by developing a brand new pump design. This change in our approach to pump design became possible only because we were able to access the expertise from outside the company.

Hiyama: Recently, we have started to work on trial studies that we carry out in a more casual manner, for example, “Let’s conduct a study on underwater robots that can be used for performing maintenance checkups of a pump!”

*6: Dry vacuum pump.

This vacuum pump does not use oil in the vacuum chamber. It is used for applications that require a clean vacuum environment such as the manufacturing of semiconductors.

Issues of research system involving concurrent work program

Interviewer: Do you think the research system will change further?

Hiyama: Since EOL was established based on the need to respond to the changes of the times quickly, I believe the basic concept of the research system will remain the same. However, there are issues that we also must resolve.

Interviewer: Exactly what kinds of problems do you face?

Sobukawa: Because we have adopted the concurrent work program, we were able to reach our major goal of filling the gap between the research work and product development for the most part. Engaging concurrently in the tasks of the business division and research places a heavy workload on one person. Our personnel carry out the researches with so much determination and energy that it is hard to imagine that they serve both positions concurrently. Nevertheless, we must find a way to reduce their workload.

Goto: Our Companies have many excellent engineers. Whether they can give their undivided attention to the engineering tasks is debatable, however, because they often have to spend time on routine tasks of the office, which the engineers should not be doing in the first place. So, we are currently working hard to reduce the time spent for routine tasks throughout Ebara so that the engineers can engage in their core task of product development. When this issue is resolved, a number of engineers who are not currently engaged in research work will be able to have the time to come back to their essential tasks and use the platform of the Ebara Open Laboratory.

Ebara Open Laboratory continues to evolve

Interviewer: Is there any other new endeavor that you are undertaking?

Hiyama: We started a platform called Ebara Open for Supplier (EOS)*7 at Ebara for collaborating with suppliers who support our researches.

Sobukawa: We are also pushing forward with a project called Ebara Innovation for “X” (EIX)*8. We view this project as a research and development platform for creating new unknown business, represented by the letter ‘X.’ To be more specific, this platform is used to conduct research on themes such as innovation of manufacturing technologies, utilization of additive manufacturing technologies (3D printer), improvement of the efficiency of designing processes using Artificial Intelligence (AI) and Information & Communication Technologies (ICT), and promotion of the smart development factory that is capable of efficient designing.

Hiyama: “Open” is the keyword for all new research systems. Open implies a research laboratory that is open to both the Ebara Companies as well as organizations outside the company. We aim at creating an environment and a co-creating space in which Ebara personnel, researchers of external institutions, and suppliers can easily assemble to exchange ideas.

For example, I hope our research laboratory becomes a place where our personnel can come with a mindset such as: “We may come across something interesting if we go there,” “Let’s drop in there and ask for some advice!” or “I have come up with this idea, and I have been wondering how I should proceed. I want you to work with me.” I also hope that people outside the company come to our research laboratory in the same way.

*7: Ebara Open for Supplier (EOS).

EOS is an organization of suppliers that provides support for our researches by collaborating with small and medium sized support groups. This platform coordinates matching with specialized technology owned by other companies and development of prototypes of special parts.

*8: Ebara Innovation for ‘X’ (or EIX).

EIX is a research and development project launched in 2016. The letter ‘X’ represents new unknown business of Ebara Corporation and this framework is used for various themes.

Interviewer: Tell me about future prospects.

Sobukawa: We are still in the stage of discussing the direction of the research laboratory. Some definite issues have been already decided.

So far, we have poured our efforts into researches that are directly associated with product competitiveness because we wanted to achieve clear successful results in order to demonstrate the effectiveness of the new research system. There is a perception, however, that such researches should be conducted by departments that are closer to product development. Therefore, from now on, we are going to shift our emphasis of research to fundamental studies.

Furthermore, there are what we have lost and where we have fallen behind due to the dissolution of the old research laboratory. So, we must perceive this fact and get those things back to our new lab.

Also, we intend to improve our marketing and research capabilities in order to carry out new researches. I think our new research laboratory must cultivate the capacity to identify technologies that have a significant impact on existing businesses, changes in the business environment, and trends of new technologies, and it must be recognized as the company brain by the management side.

The laboratory requires to perform numerous functions, for example, research on technology trends, projects for new research themes to prepare for the future, strengthening of the fundamental technological competence, promotion of researches that can improve product competitiveness, support for development of the business divisions, and support for handling claims. I believe that the new laboratory must perform these functions reliably and the research system must continue to evolve in accordance with the requirements of Ebara so that our company can maintain its competitive power and move ahead to the future.

Interviewer: I have high expectations of the research and development carried out by Ebara in the coming years. Thank you for your time.

Remarks: The interview in this article was conducted by a facilitator from outside the company who also prepared and edited the article.

Recommended articles

Inquiry about Ebara Engineering Review